Catalogue

Cover coat enamel frit for steel

Key words:

enamel frit , porcelain enamel frit , inorganic pigment

Classification:

Product Description

Cover coat enamel frit is applied on the surface of enamelware with different colour. The firing temperature is lower than ground coat.

Mill addition ratio and requirements of Titanium frits:

Frit | 100 | Urea | 0-0.5 |

Clay | 5-6 | Potassium chloride | 0-0.2 |

Water | 45-55ml |

|

|

Fineness | 1.0~2.0g/150mesh.100ml | Specific Gravity of Slip | 160~168g/100ml |

Mill addition ratios and requirements of Antimony frits:

Frit | 100 | Water | 40-50ml |

Clay | 6-7 |

|

|

Fineness | 1.0~2.0g/150mesh.100ml | Specific Gravity of Slip | 170~175g/100ml |

Lifa cover coat enamel frit product list:

Product Name | Code No. | Firing temp(℃) | Coefficient of thermal expansion(*10ˉ 7 ) |

High Temp Titanium White Frit | ETW-203 | 810-850 | 260.7 |

Low Temp Titanium White Frit | ETW-222 | 780-820 | 280.7 |

Super White Cover Coat Frit | 2200 | 800-830 | 275.5 |

Antimony White Cover Coat Frit | 3# | 800-820 | 283.4 |

Low Temp Titanium Cream Frit | ETC-223 | 780-820 | 284.3 |

High Temp Titanium Cream Frit | ETC-204 | 810-850 | 283.5 |

Titanium Lake Blue Frit | ETG-206 | 810-850 | 293.4 |

Titanium Apple Green Frit | ETG-208 | 810-850 | 292.5 |

Titanium Ivory Frit | ETC-214 | 810-850 | 282.5 |

Royal Blue Cover Coat Frit | ECF-309 | 800-840 | 302.2 |

Matt Enamel Frit | 2310 | 800-830 | 326.8 |

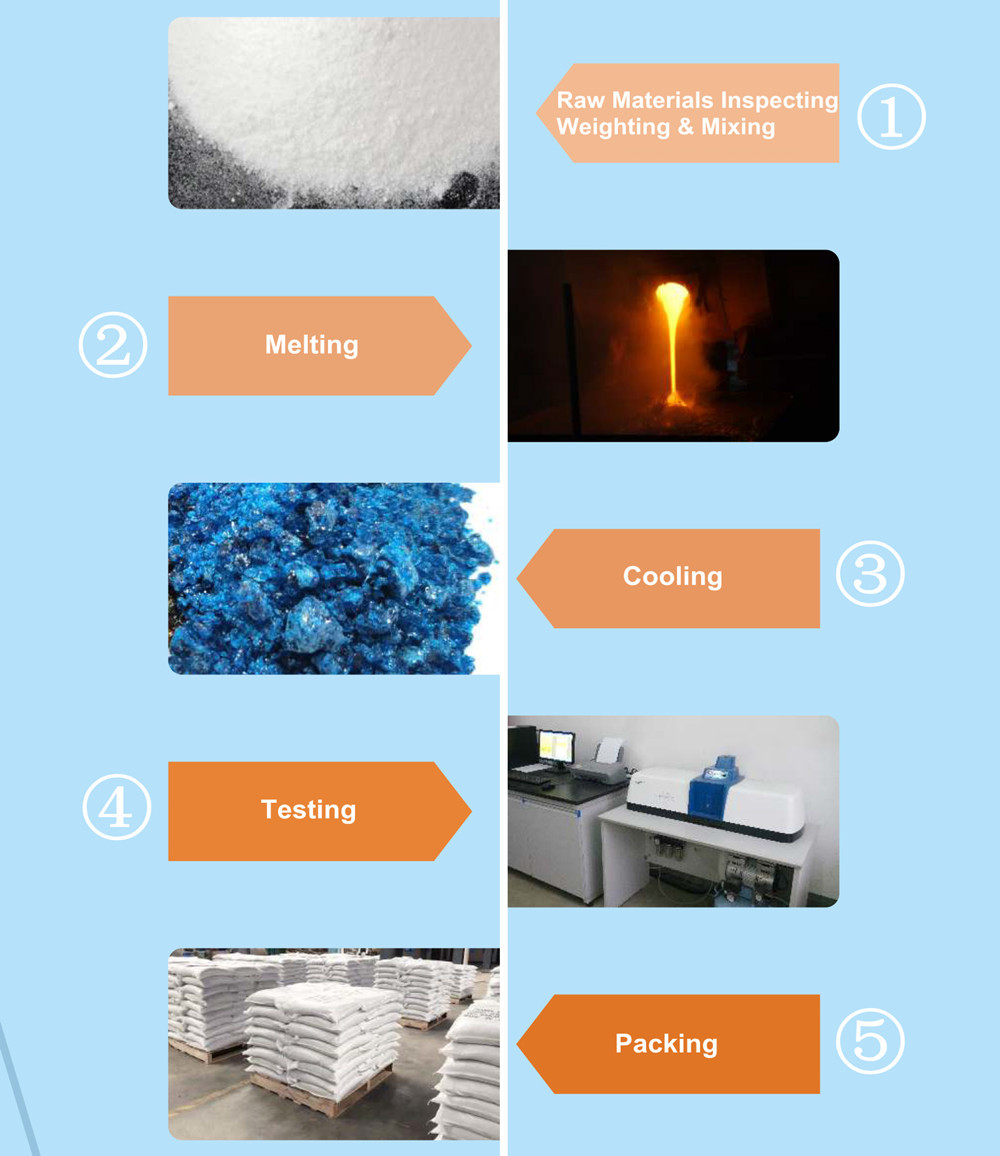

Process of Production

Related Products

online message