Catalogue

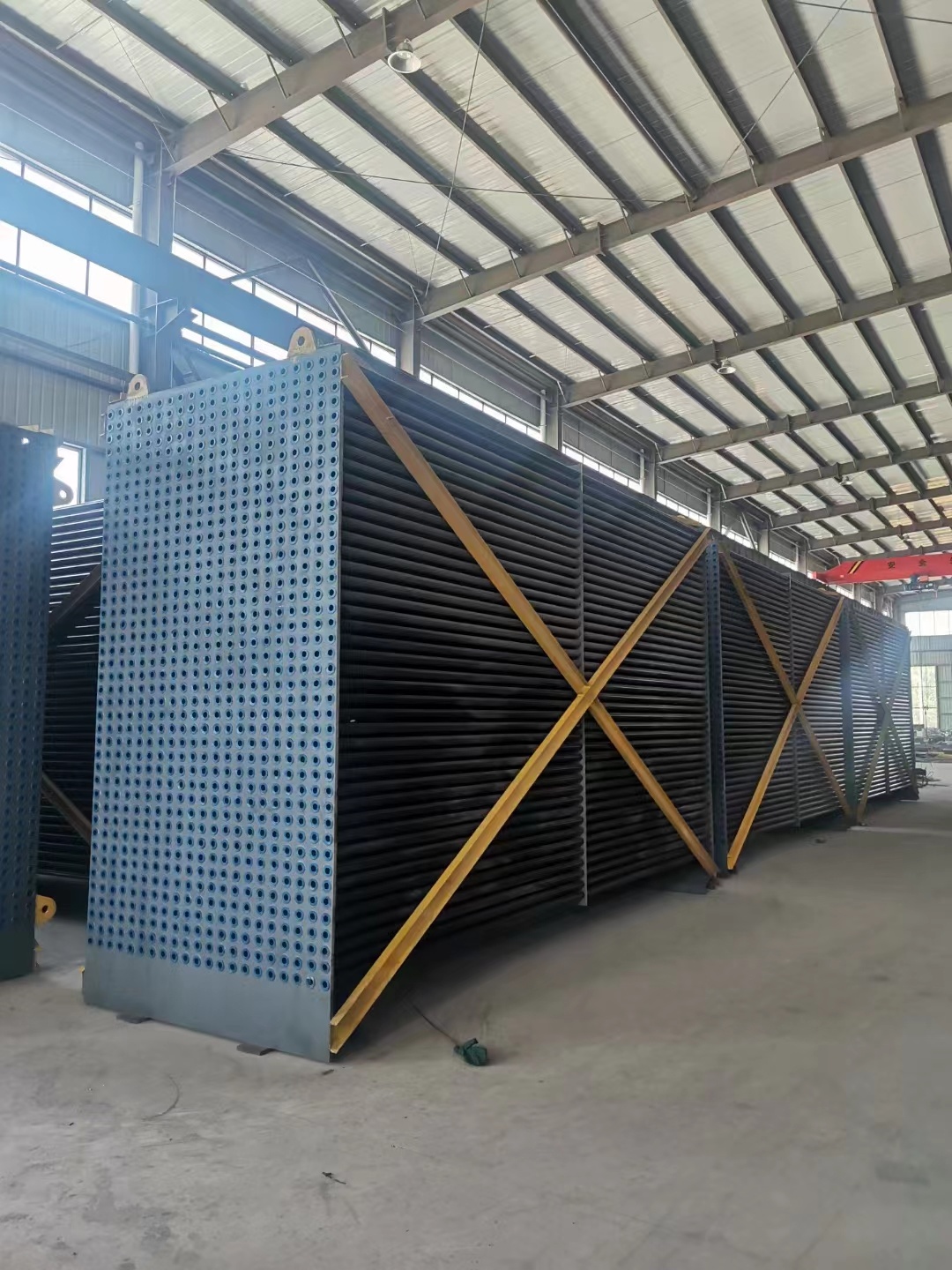

Acid resistant enamel powder for pipes of air pre-heater

Key words:

Enamel porcelain glaze, inorganic pigment

Classification:

Product Description

Acid resistant enamel powder for pipes of air pre-heater

1. Material Ratio:

Pre-grinding Powder: 100

Water: 40

2. Approval Standard:

a. Appearance: Gray powder. After firing, the coating is in conformity with standard template which is smooth, glossy and with no flaw on surface.

b. Firing temperature: 850-870℃.

c. Adherence: ≧ grade 2

d. Acid assistance: ≧AA level

e. Fineness: 140 mesh. Pass 100g such powder through a 150-mesh sieve, there will be only 1-3g residue.

3. Test Method:

a. Soak the pre-grinding powder and water in proportion of 100/ 40 for 1~2 hours.

b. Pass them through 80-mesh sieve and keep the consistency at 165~170g/100ml, (1.65~1.70g/cm3).

c. Cover 150-200 micron such enamel out of a pipe which is 2mm in thickness and 25mm in diameter, fire them at 850-860℃ for 6~8 minutes.(This process could be repeated once more. )

d. Compare them with samples made from normal powder.

4. Introduction:

140~150 mesh light blue powder. Pass 100g such powder through a 150-mesh sieve, there will be only 0-0.5g residue. This product is used for enameling on corrosion-resistant pipes, which is delicate in quality and has a strong resistance against acid/ alkali. The temperature should be very well controlled when firing in order to accomplish the ideal effect.

5. Production Requirements:

All the qualified enamels should be grinded to 140-150 mesh first and mixed with eligible additives. Then make screening and packing after fineness meets the requirements.

Related Products

online message